The AFP range provides excellent rag handling and power up to 550 kW 50 Hz 600 kW 805 hp 60 Hz. Water requirements will slowly increase as the packing gets worn out and eventually needs to be replaced.

Top 10 Slurry Pump Feed Tank Suction Pipe Design Recommendations

Water and organic waste matter enter the chamber and are reduced to slurry as the macerator blades rotate at 3600 RPM.

. The amount of gland water required depends mostly on pump design and how worn the packing is. The compression ratio of the injector is. Normal gland water flow rates for slurry pumps can be as low as 5 m³hr to as much as 25 m³hr if the pump packing is really.

A new packing will take less gland water. Fluid feed rate and operating pressure range are the key parameters of an injector and vacuum pressure and evacuation rate are the key parameters for an ejector. The entrained suction fluid may be a gas a liquid a slurry or a dust-laden gas stream.

Depends on your space and requirements Dredge Slurry Dewatering System Dredge Slurry dewatering system is dredge slurry separation system consist of shale shaker desander desilter or decanter. The material is picked up by the suction of a pump then transported through a pipeline in the form of a slurry. Usually ship-form in design a hopper dredger deposits the dredged material in an on-board hopper for transportation.

The submersible sewage pump type ABS AFP range offers reliable and economical pumping of heavily polluted sewage in commercial industrial and municipal applications. Compression ratio and the entrainment ratio may also be defined. We can design and build both vertical tanks rectangular tank round tanks etc.

The unit pumps the effluent upward to 15 ft. GN Solids Control design and manufacture different size of liquid mud plant according to your need. Both mechanical and hydraulic designs are common for loading the hopper as well as for discharging the dredged material.

The centrifugal force causes the reduced solids to be ejected through a grill into the container where it is picked up by the impeller pump mounted beneath the motor.

New Pump Box For Sale By Savona Equipment

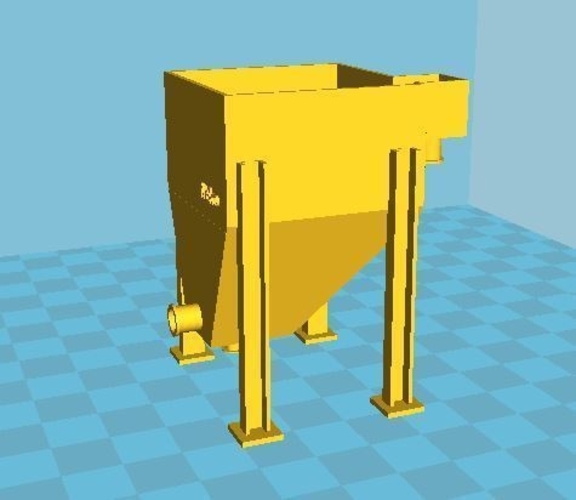

3d Printed Slurry Pump Box By Neko Rodrigues Pinshape

New Pump Box For Sale By Savona Equipment

Pump Boxes Slurry Pumps Alberta Oil Sands Equipment

0 comments

Post a Comment