The mix design and proportions of the materials have a major effect on the. Concrete Mix Design Wet Cast Slump Dry Cast no Slump Combination of Art and Science 2122015 2 3 Water Cement Aggregate.

The American Concrete Institute.

. The typical method by which zero-slump specimen cylinders are made cured and tested conforms to the practice established by CSA A232-00 Test No. The slump should be between 3 and 4 inches and the placement method is by pumping. Do you know-Self compacting concrete has a slump value of more than 650 mm.

The flow is measured in accordance with BS EN 12350-5. Stop Overspending On Textbooks. S1 F1 W0 and C1.

Ad Shop Concrete Cement Stucco Mix Today Get Great Deals On Quality Products. According to ACIs Cement and Concrete Terminology ACI 116R-90 no-slump concrete is freshly mixed concrete exhibiting a slump of less than 14 inch. Procedure of Slump Test.

It is useful to check concrete mix batches on site before pouring concrete. Pervious concreteNo-slump pervious concrete mixtures commonly use a single coarse aggregate size consisting of ASTM C33 size No. Find the Right Material For Every Job.

But how much sand stone. Need to maintain time period and workability of concrete. Place the nixed concrete in the cone to about one-fourth of the height ie.

Let us consider the following concrete mix design example. Pervious concrete contains little or no fine aggregates such as sand it is sometimes referred to as no-fines concrete. 67 have been used.

Founded in 1904 and headquartered in Farmington Hills Michigan USA the American Concrete Institute is a leading authority and resource worldwide for the development dissemination and adoption of its consensus-based standards technical resources educational programs and proven expertise for individuals and organizations. A zero-slump concrete mix can be used to manufacture a wide variety of precast concrete products just as a conventional wet-cast or SCC self-consolidating concrete mix can. Pervious concrete is a zero-slump open-graded material consisting of cement coarse aggregate admixtures and water.

8 3 8 inch to No. Proposed Revision of ACI 211-65. Ating compressive strength of zero-slump concrete are outlined in CSA A234-00 Section 17811 Typically the compressive strength of precast concrete is quantified by using test cylinders.

Basic Concrete Mix Design Materials Pounds of material SG. Each mix prepared is tested in laboratory after hardening to verify whether it. Also need to be concrete production economic and standard strength as per requirements.

Compact concrete uniformly all over the area by 25 times with the help of tamping rod. Also need to achieve durability of concrete. Ad Read this book and 900000 more on Perlego.

8 although aggregate sizes No. Abs Volume Cement 667 315 339-Total Cementious 667 Miller Stone 1590 26 980. O Less than 50 cubic yards o Design stress in concrete 2500 psi o Concrete specified compressive strength of 4000 psi or greater Non structural slabs supported directly on the ground Concrete foundations for lightweight fences recreational equipment.

Concrete mix is not properly mix. The content of Pervious concreteis another form of no-slump concrete and it is. The concrete slump test is a simple and easy test that measures the consistency of concrete before it sets.

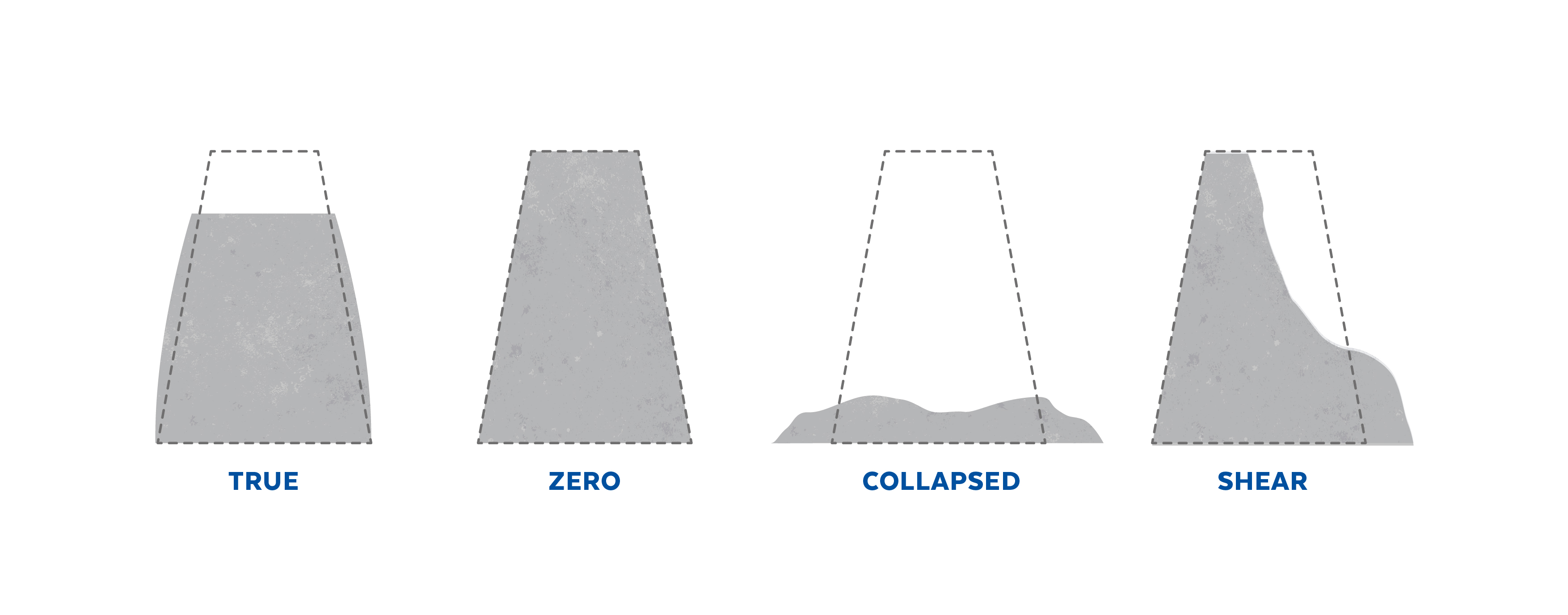

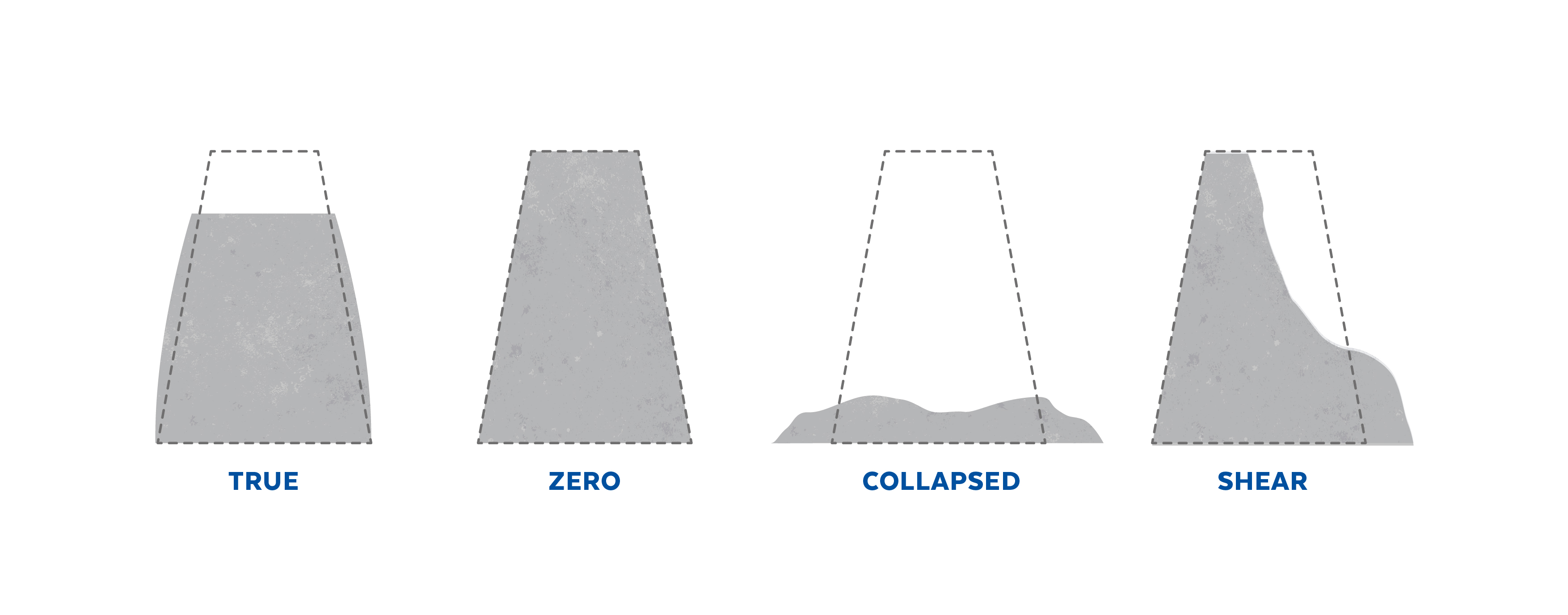

The following is a design guide for selecting proportions for initial concrete mix design for normal weight concrete. Because of its unique design mix pervious concrete is a highly porous material that allows water particularly rainwater to filter through reduces flooding and heat concentration by up to 4C and helps to prevent skidding on wet roads. This type of slump is not recommended in any type of the concrete mix design.

A zero-slump concrete mix can be used to manufacture a wide variety of precast concrete products just as a conventional wet-cast or SCC self-consolidating concrete mix can. Quality reading in one simple space. - for same slump Mix design with Cement Fly Ash Proportion the mix to yield 27 ft3.

Basic Concrete Mix Design Materials Pounds of material SG. In the United Kingdom the slump test is measured in accordance with BS EN 12350-2. Zero-slump concrete is defined in the same document as concrete of stiff or extremely dry consistency showing no measurable slump after removal of the slump cone.

Zero slump concrete mix design Written By eugenianopachai23739 Wednesday May 18 2022 Add Comment Edit. The workability requirements of each mix can also meet using this method from zero slump to the 150 mm slump. To avoid facing problems on-site as honeycombing a structure.

Abs Volume Cement 667 315 339-Total Cementious 667 Miller Stone 1590 26 980 Evert Sand 1242 265 751 Water 300 1 481. Lightweight High-Performance Concrete Masonry-Block Mix Design. Pervious concreteNo-slump pervious concrete mixtures commonly use a single coarse aggregate size consisting of ASTM C33 size No.

Vibratory Compactation Study of Zero-Slump Concrete. Using design concrete mix one can design various grades of concrete from as low as M10 grade to higher grades such as M80 M100 can also be prepared. Structural Concrete BB 2009026.

The diameter of tamping rod should be 16mm and length 600mm. Beside intentional use for specific application the reason for collapse slump can be. Find out more about concrete slump and its American European and Indian standards the differences in their procedure and much more.

Pervious concrete pavement in rural areas is a unique and effective means to achieve important. The mixture reserves its shape after the removal of the mold with a slump less than 14 6mm. This guide references ACI 2111-91 Reapproved 2009 Standard Practice for Selecting Proportions for Normal Heavy weight and Mass Concrete specifically Chapter 6 Procedure and Appendix 1 Metric SI System.

However if your market demands higher volumes and quicker turn-around delivery for a given product a dry-cast process may be just the ticket to increase. Water cement ratio is so high that the concrete is highly workable. This creates a void content in the mixture of 15 to 25.

Recommended Practice for Selecting Proportions for No-Slump Concrete. And negative-slump concrete is. Start your free trial today.

Start Your Project Sooner with Store Pickup. The exposure conditions following the ACI 318-19 are briefly a follows. Place the slump cone on a level smooth waterproof base.

A concrete with a specified compressive strength of 3750 PSI is required for a slab on ground.

Zero Slump Concrete Mix Design Download Scientific Diagram

Zero Slump Concrete Mix Design Download Scientific Diagram

Zero Slump Concrete Mix Design Download Scientific Diagram

Concrete Slump Tests Measuring The Workability Of Concrete Total Concrete

M50 Concrete Mix Design Steps Is 10262 2009 Is 456 2000 Eigenplus

No Slump Concrete Mix Designs Download Table

0 comments

Post a Comment